Remote control and monitoring of the engine room of a naval military vessel.

| Project: |

Remote control and monitoring of the engine room of a naval military vessel. |

| Hardware: |

3x PCM4 Q87- ISIC, 3x DuraPANEL 24- ISIC |

| Control stations: |

7x PLC Simatic S7-ET200SP, 1x PLC Simatic S7-1200 |

| Implementation: |

HG Solutions Sp. z o.o., http://www.hgsolutions.pl |

| Date of commission: |

2020 |

System design and functionality:

The PROMOTIC SCADA system was used to create a system for remote control and management of the engine room of a naval vessel.

The engine room monitoring and control system consisted of eight PLCs, to collect signals, process information, send control signals and exchange data. The PLC devices are located mainly in the engine room of the ship. They are interconnected in a circular topology using an optical standard. This allows fast data exchange with low failure rates. Within the communication ring, the system consists of three PROMOTIC operator stations located in control room of the engine room, the PROMOTIC operator station on the captain's bridge, a PROMOTIC operator station in the ship's power plant room and three PROMOTIC operator stations located in the crew rooms.

The operator stations located in the engine control room are equipped with two 22" monitors with Full HD resolution. The remaining operator stations are equipped with one monitor.

The operator's counters in the engine control room are the three main pillars on which the data acquisition and visualization is based. The other operator consoles use the Web standard to display the visualization, which allows operation of the system from a Web browser. In the event of an emergency, the control consoles in the ship's engine room and on the bridge can be switched to emergency operation mode.

Each of the operator stations outside the engine control room has its own assigned base station, from which it downloads data and graphical visualization using the Web standard.

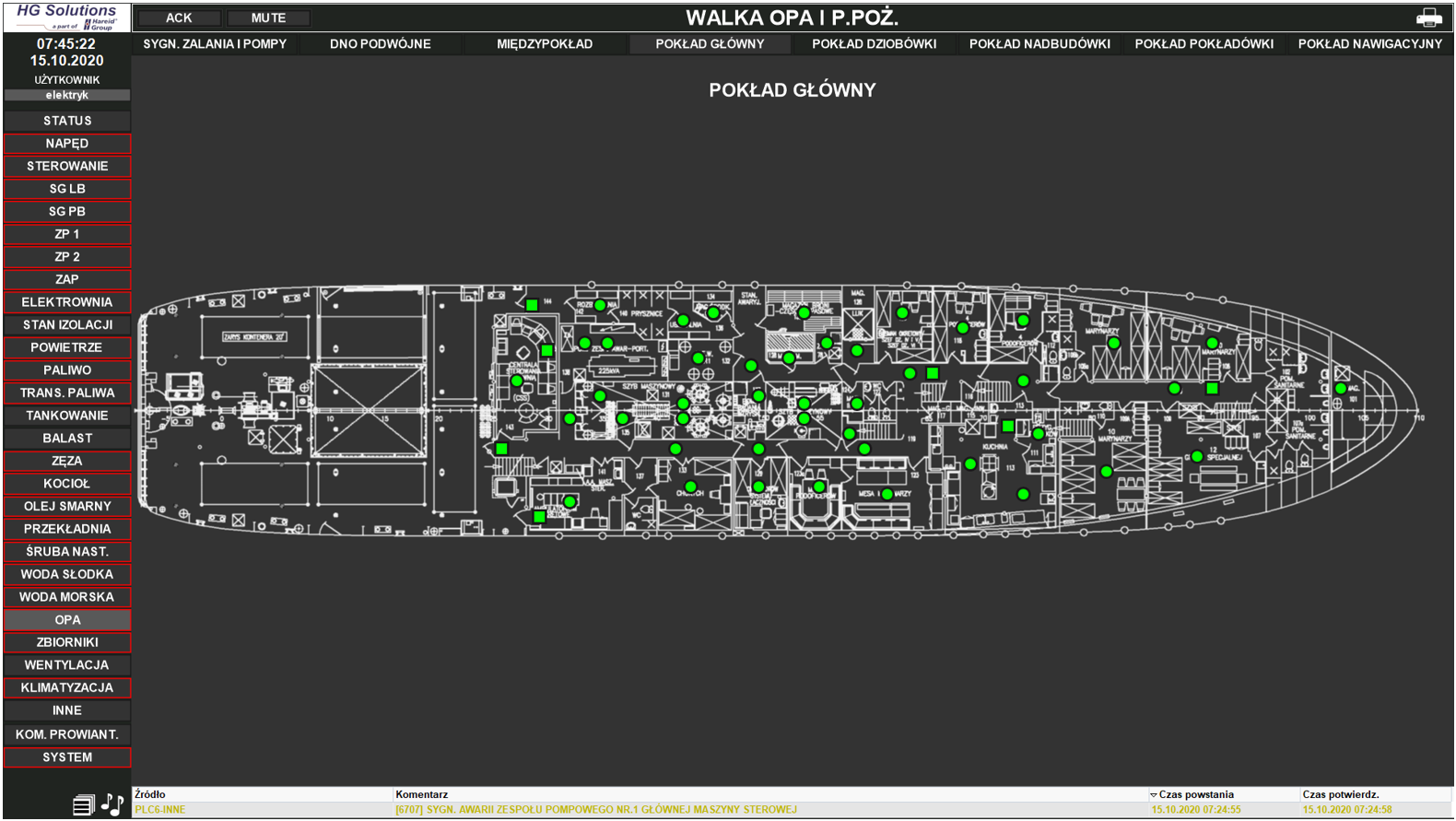

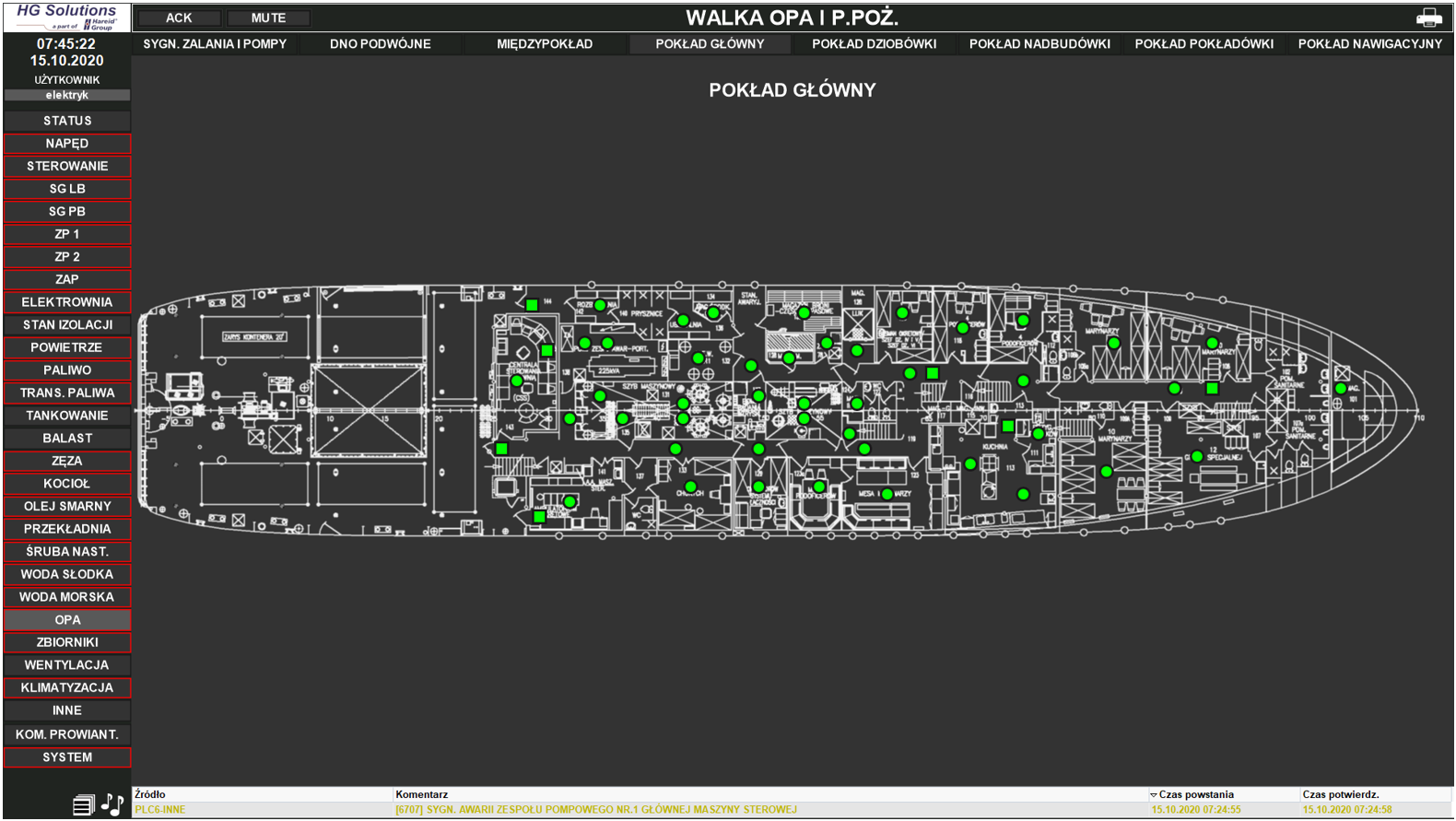

Main deck

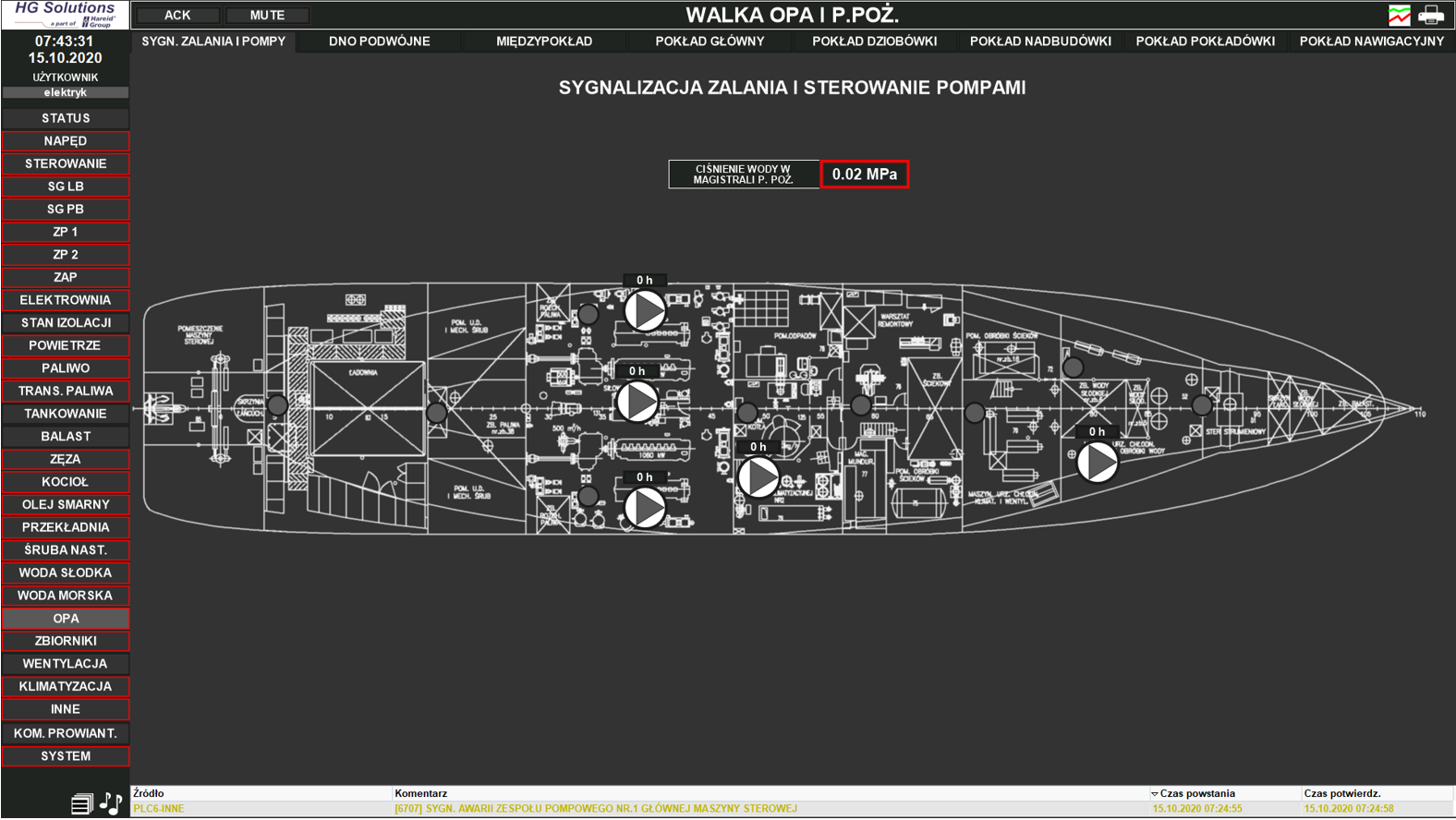

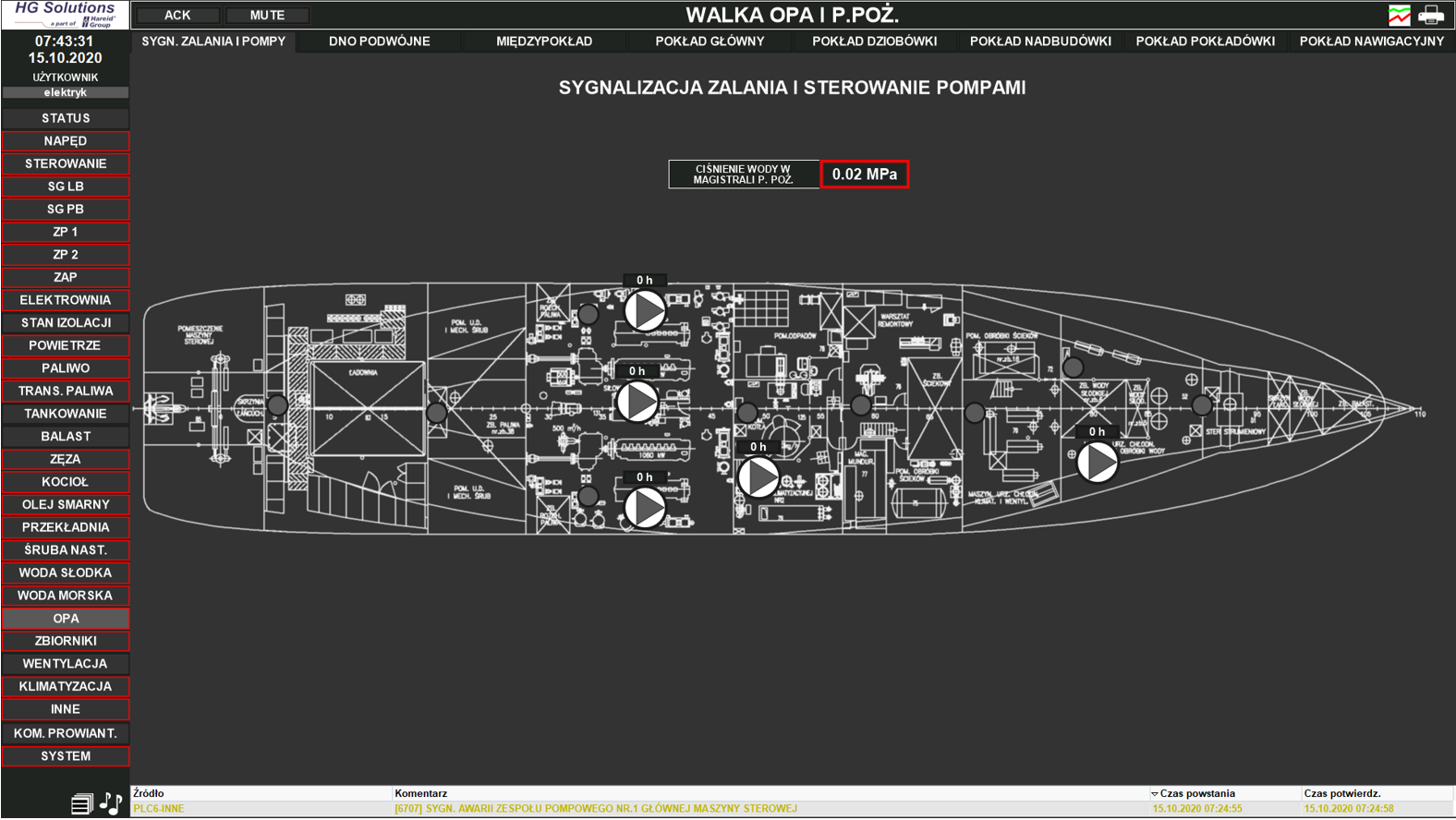

Flooding signalling and pump control

Thanks to the openness of the system and the support of the CANVAS technology by the PROMOTIC system, the monitoring and control system of the engine room was retrofitted with a special redundancy module for this application. The PROMOTIC system, as a master system, supervises at least the following systems:

- main propulsion engines

- generator engines

- clutch and set screw system

- seawater system

- freshwater system

- lubricating oil system

- steering oil system

- compressed air system

- Engine room ventilation system

- fuel handling system

- ballast system

- Hold system

- ship's power plant system

- fuel tank gauging system

In addition, the engine monitoring and control system controls:

- Alarm system in the engine room.

- Alarm archiving system, logs.

- Data recording into the

MS SQL database for external reporting system.

Picture 1: Visualization of the propulsion system. This is a summary screen of the drive system. This screen contains the most important information about the components of the ship's propulsion system. Includes: main engines, drive gears, drive system couplings, propellers.

Picture 2: Visualization of the main engine parameters. Displays the most important parameters of the diesel engine.

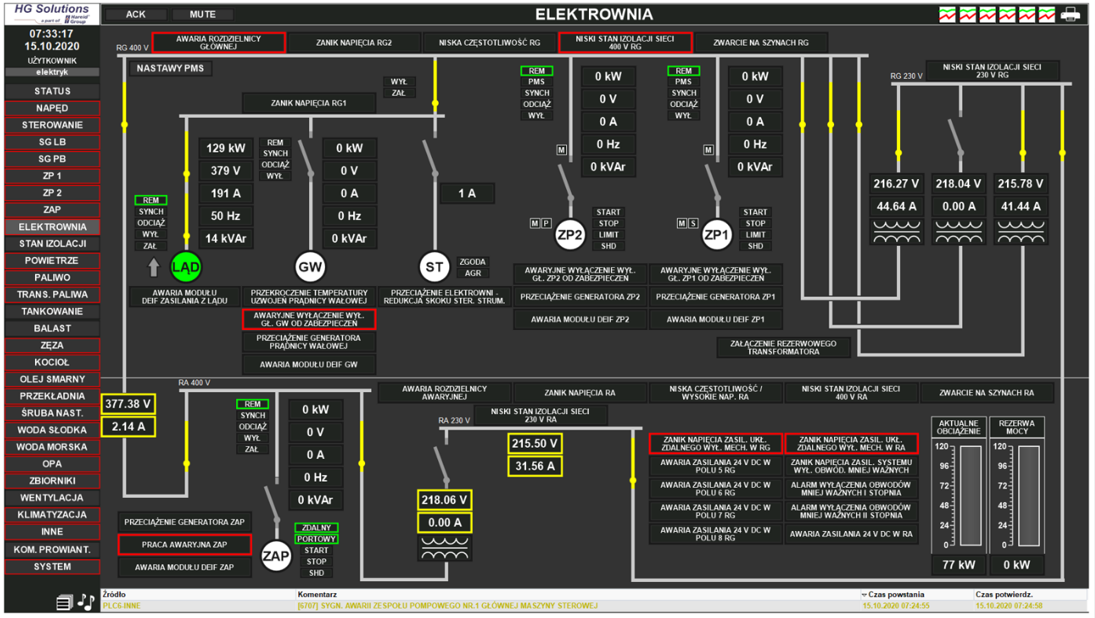

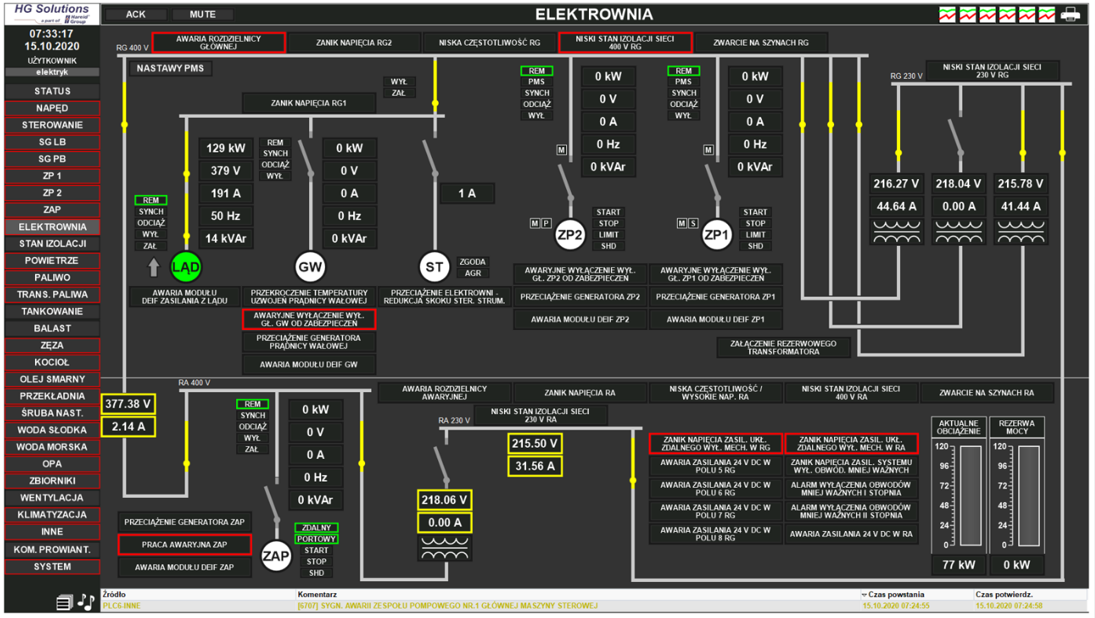

Picture 3: Visualization of the ship power plant. Displays the ship's power system. The ship's power plant is equipped with a PMS whose task is activating the power generators in the event of a blackout, controlling the efficiency of the power plant depending on the current energy demand (starting/shutting down the generators, reducing the load).

Picture 4: Visualization of the engine room ventilation system.

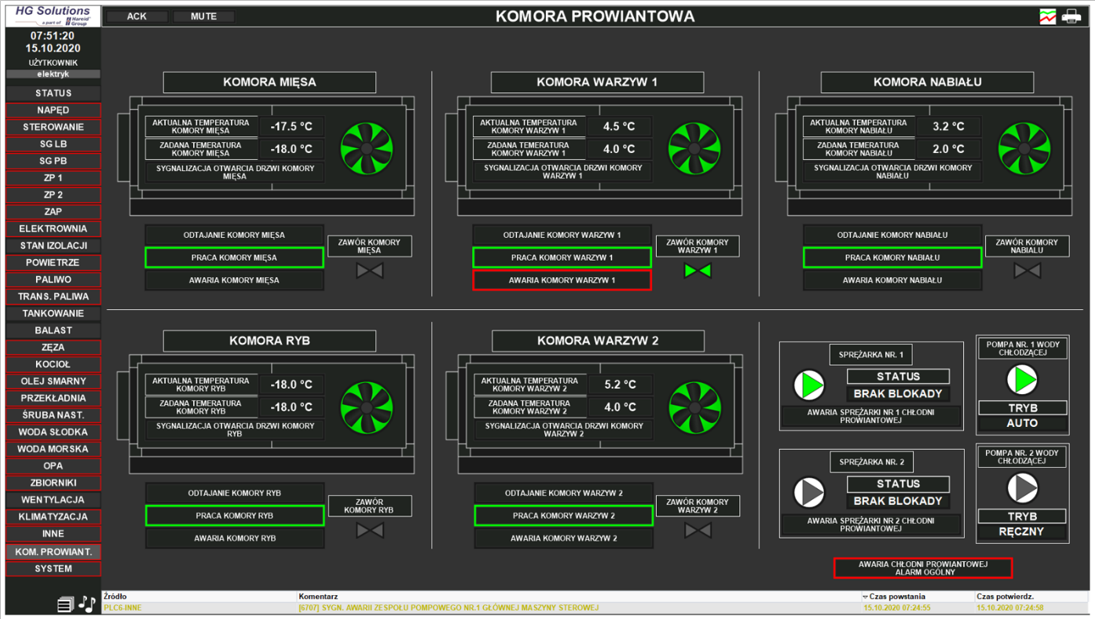

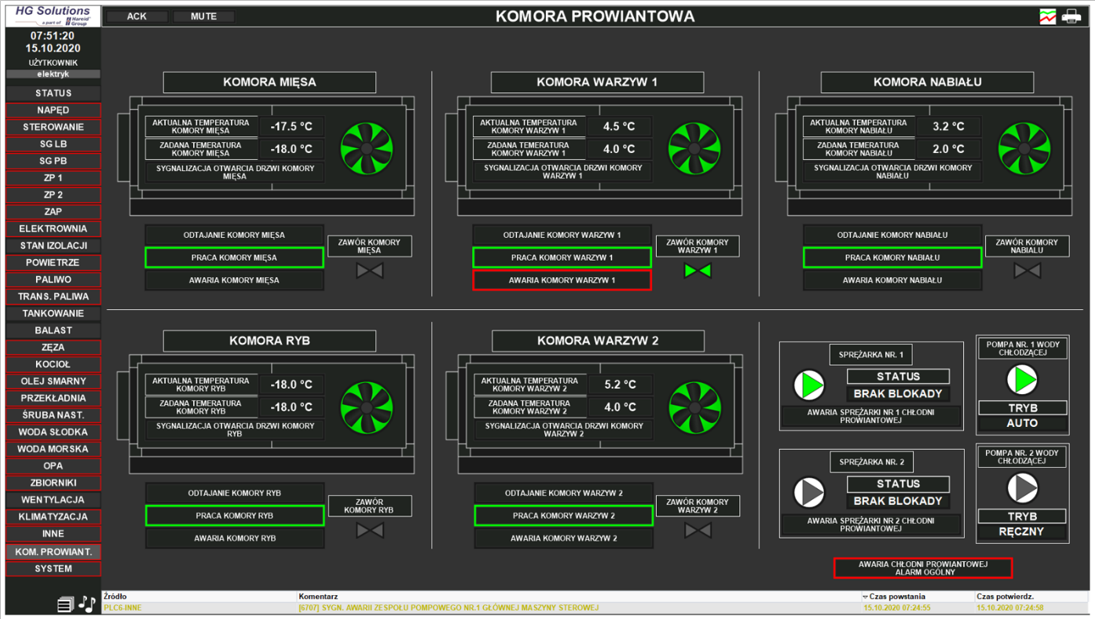

Picture 5: Visualization of the ration chambers.

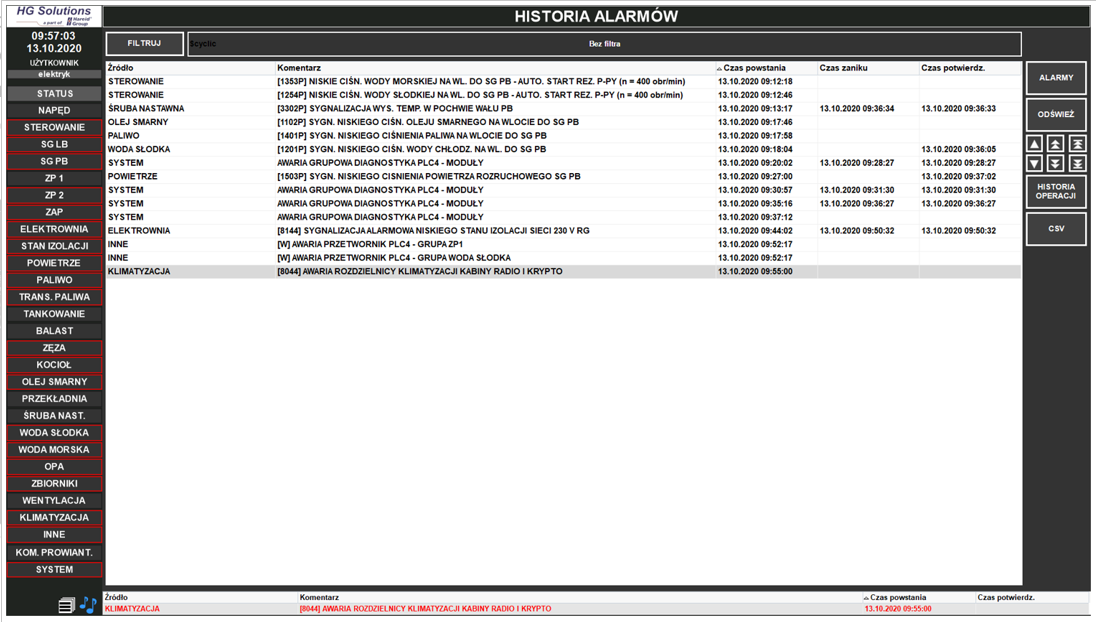

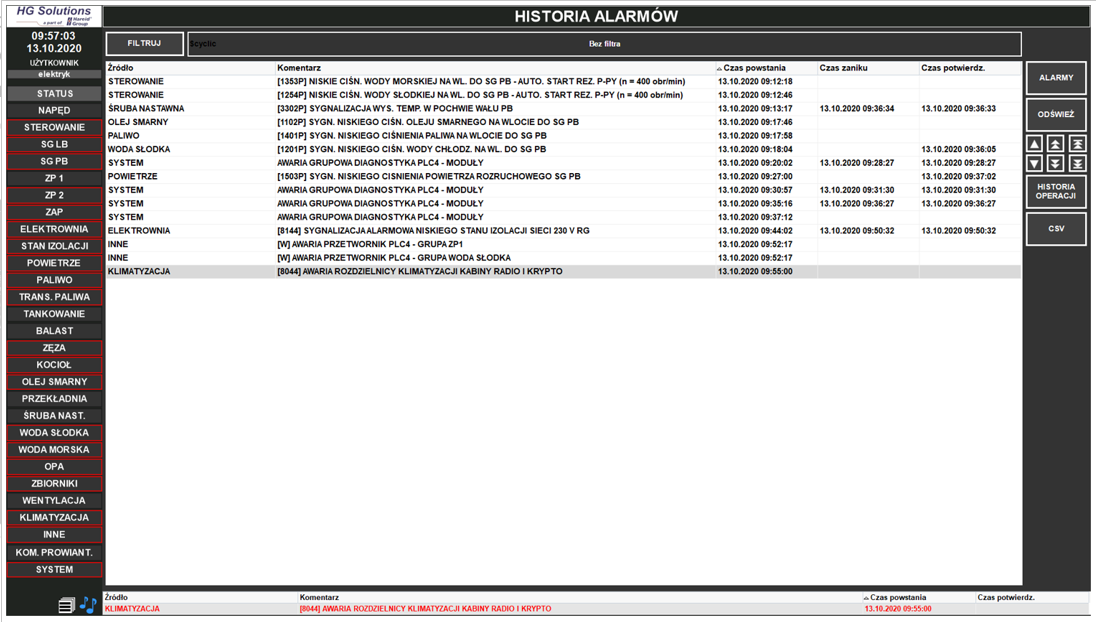

Picture 6: Visualization of the alarm system.

Main deck

Main deck

Flooding signalling and pump control

Flooding signalling and pump control

Picture 1: Visualization of the propulsion system. This is a summary screen of the drive system. This screen contains the most important information about the components of the ship's propulsion system. Includes: main engines, drive gears, drive system couplings, propellers.

Picture 1: Visualization of the propulsion system. This is a summary screen of the drive system. This screen contains the most important information about the components of the ship's propulsion system. Includes: main engines, drive gears, drive system couplings, propellers.

Picture 2: Visualization of the main engine parameters. Displays the most important parameters of the diesel engine.

Picture 2: Visualization of the main engine parameters. Displays the most important parameters of the diesel engine.

Picture 3: Visualization of the ship power plant. Displays the ship's power system. The ship's power plant is equipped with a PMS whose task is activating the power generators in the event of a blackout, controlling the efficiency of the power plant depending on the current energy demand (starting/shutting down the generators, reducing the load).

Picture 3: Visualization of the ship power plant. Displays the ship's power system. The ship's power plant is equipped with a PMS whose task is activating the power generators in the event of a blackout, controlling the efficiency of the power plant depending on the current energy demand (starting/shutting down the generators, reducing the load).

Picture 4: Visualization of the engine room ventilation system.

Picture 4: Visualization of the engine room ventilation system.

Picture 5: Visualization of the ration chambers.

Picture 5: Visualization of the ration chambers.

Picture 6: Visualization of the alarm system.

Picture 6: Visualization of the alarm system.