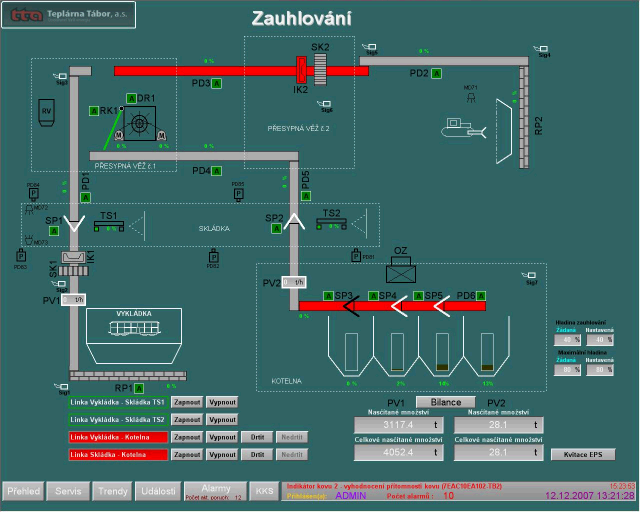

Control and monitoring of coal feeding - Heating plant Tábor a.s.

| Hardware: | 1x OS (Panel PC Advantech, Windows OS XP Professional) |

|---|---|

| Control stations: | 1x PLC GE-Fanuc (Ethernet TCP/IP), GE OPC server. |

| Date of commission: | 2007 |

| Application designer/company name: | MPC System, spol. s r.o., http://www.mpc.cz |

Control and monitoring of coal-feeding lines for boilers. Complete control and monitoring of line status, supervising the coal levels in containers.:

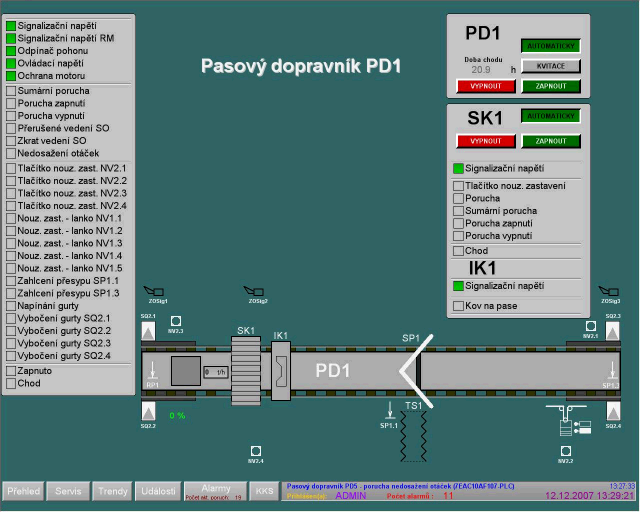

Controlling three coal-feeding lines for boilers. Control and status signalling of conveyor belts, lift-up carts, drop-off ploughs. Monitoring the coal levels in containers, storage statistics. Signalisation of error states of switchroom, belts, ploughs, shutters, etc. Failure signals, value trends. The communication between the PC and the PLC is implemented by the Ethernet TCP/IP protocol via the GE OPC server. The control PC is equipped with touch panel and is located in the coal-feeding switch room.

Size of the application: aprox. 1300 variables.

See also:

Navigation:

- Control and monitoring of coal feeding - Heating plant Tábor a.s.