Supervision system for heatpumps operation - TC MACH

1. System main functions

The heatpump supervision system is a complex and open software solution, that permanently monitors and evaluates the operation of hetpumps. The core of the system is represented by a database server that provides:

The heatpump supervision system is a complex and open software solution, that permanently monitors and evaluates the operation of hetpumps. The core of the system is represented by a database server that provides:

- continual communication with all heatpumps connected to the system

- evaluation of operational states of the heatpumps

- archiving all important system data

- providing data to visualization client stations

- administrative configuration and parametrization

The operational states and possible error reports of the heatpumps in Czech Republic and abroad are being continuously monitored. All heatpumps are equiped with the Internet connection (ADSL, GPRS, etc.). All user and operator accesses are managed via the Web. The software application includes sofisticated system of user permissions, that ensures secure access of different users:

- system operator

- coordinator

- heatpump users

- service technicians

- system administrator

2. Data management and archive

All application data is stored in the MS SQL database. The system continuously keeps and archives the heatpump operational data. There are also the system parameters, operation journals, alarm texts etc. in the database. The central control station stores the history of error states and service interventions. Based on these reports, the expert database is created, that is then used by the heatpump manufacturer for furthher analysis.

All application data is stored in the MS SQL database. The system continuously keeps and archives the heatpump operational data. There are also the system parameters, operation journals, alarm texts etc. in the database. The central control station stores the history of error states and service interventions. Based on these reports, the expert database is created, that is then used by the heatpump manufacturer for furthher analysis.

The system is modulary and very general - with the possibility to add dynamically additional heatpumps and configure them. These operations are done by the system administrator via the Web interface for SQL data management. In the system, it is possible to define:

- heatpump types and parameters

- countries and languages where the heatpums are operated

- system users (endusers)

- alarm messages and error codes

- events and reports

- daylight-saving time / standard time transitions for specific countries

- permission levels and access codes

- additional data and parameters

3. Customer interface

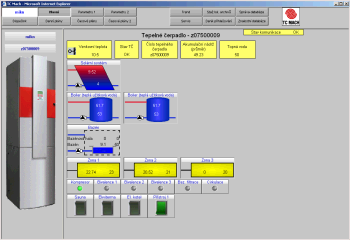

The end user can access the system at any time and use the Web interface for monitoring the connected devices (see picture 1).

The end user can access the system at any time and use the Web interface for monitoring the connected devices (see picture 1).

- heatpump

- solar heating system

- boiler

- pool

- additional objects

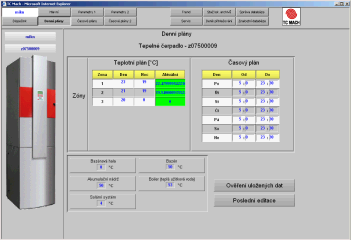

The daily plan panel allows to set the desired temperatures for specified zones and define the time programs (see picture 2). The temperatures and another parameters are archived, allowing the customer to view the current status and also the history of specific system values (e.g. the temperature of heating water, outer temperature, pool water, etc. – see picture 3) The system allows to check the heatpump status from any place in the world and do the necessary setup if needed.

4. Communication with heatpumps

The central control centre monitprs the heatpumps and periodically checks the operational status periodicaly. The communication is optimized for speed and data volumes. The system provides:

The central control centre monitprs the heatpumps and periodically checks the operational status periodicaly. The communication is optimized for speed and data volumes. The system provides:

- Reading and evaluating the actual data from the heatpumps

- Reading the local data archives stored in the heatpump control system (on demand by operator or service technician)

- Receive and process the daily data for statistics

- Receive and process the alarm data (acknowledgment, writing to the database, etc.)

- Sending SMS messages or e-mails to the service center if an error occures

- Time synchonization for heatpump control systems – according to valid time zones for current countries.

5. Service and maintenance

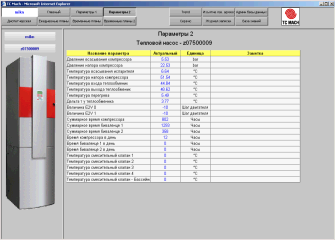

The monitoring system continuously checks the heatpump states. In the case of malfunction, the system automatically finds the optimal service technician in the database and informs him by SMS or e-mail about the problems of current heatpump. The technician can then connect to the system and check the heatpump status via the Web interface from any PC connected to the Internet. The multilingual system allows the service technician to choose the language to be used for communication and data presentation from the specific heatpump (see picture 4 – heatpump parameters).This way the service technician can analyse the system quickly and find the cause of malfunction. The information regarding the problem solution is then entered as notes for the corresponding alarm state, that indicated the malfunction for further reference. If the on-site intervention is needed, then the closest technician is contacted and the correction is done uder the main technician remote supervision. The central control center can also check whether the service intervention has been completed within the agreed time. If there is a service delay, then the system generates an e-mail message and sends it to the responsible person, that is then able to make the necesaary corrective actions.

The system stores the operational staus data in the database, including the errors, alarms and malfunctions. this comprehensive database allows the technicians to analyse the heatpump opeartion and provide preventive actions.

6. Resume

The central control centre application software, the data server and all Web interfaces for monitoring and maintenance have been created by the use of the PROMOTIC system. The system has been developed under the cooperation with the TC MACH company (see: http://www.tepelna-cerpadla-mach.cz), that is one of the leading manufactirers of heatpumps in the Czech Republic and abroad. The heatpums are equiped by the AMiT control systems by default. The system is running since 2007 and is continuously being improved and expanded by the TC MACH experts.See also:

Navigation:

- Monitoring of heatpumps operation