Warehouse automated manipulator control system - Olpran Olomouc

Środki techniczne: 2x PC, SO Windows XP, Stacje sterujące: Mitsubishi

Wykonanie: MICROSYS, spol. s r.o., Ing.Miroslav Horák-HOZST

Data oddania do eksploatacji: 2006 - 2007

There is a warehouse stacker system running in the company Olpran Olomouc, that manages all goods receipt/issue operations, manipulates the mobile warehouse stacker and keeps record of all the goods on stock. The warehouse contains 44 columns and 6 stores where a variable ilość of cargo boxes (bicycles and other material) can be stored. The dimensions of the boxe vary według the contents.

The warehouse system has been created w systemie PROMOTIC. The system controls all warehouse operations, including the mobile warehouse stacker, records all performed warehouse operacje, reads and evaluates the bar codes of stored goods and multiple additional operacje. The warehouse operations are being executed in an optimized way in ordet to satisfy the needs of the enduser.

The warehouse system has been created w systemie PROMOTIC. The system controls all warehouse operations, including the mobile warehouse stacker, records all performed warehouse operacje, reads and evaluates the bar codes of stored goods and multiple additional operacje. The warehouse operations are being executed in an optimized way in ordet to satisfy the needs of the enduser.

The control system of the stacker is connected via the Intranet into the HELIOS enterprise system, where all the warehouse operacje are recorded and processed. The data transfers between both systems is managed by MS SQL database interface. Both systems have mechanisms identifying the record states (waiting for warehouse intake, on stock, cancelled, itd.) a thus securing fluid request transfers between both systems.

The warehouse stacker system runs on 2 PC stacje:

- warehouse operator PC – vizualization and data server

- industrial PC - placed in the switch-board of the mobile stacker

The industrial PC in the mobile stacker:

The commands for warehouse operations are transmitted wirelessly from the warehouse operator PC into the industrial PC, that is placed in the mobile stacker (rail cart). The mobile stacker is equipped by an extensible frame, for executing the warehouse operacje. Aplikacja running on the industrial PC komunikuje with the manipulator command system and transfers the commands from the superior PC of the warehouse operator. The movement of the mobile stacker is managed by Mitsubishi PLC based on the commands from the industrial PC. In the automatic mode, aplikacja requires no interference from the operator.

The commands for warehouse operations are transmitted wirelessly from the warehouse operator PC into the industrial PC, that is placed in the mobile stacker (rail cart). The mobile stacker is equipped by an extensible frame, for executing the warehouse operacje. Aplikacja running on the industrial PC komunikuje with the manipulator command system and transfers the commands from the superior PC of the warehouse operator. The movement of the mobile stacker is managed by Mitsubishi PLC based on the commands from the industrial PC. In the automatic mode, aplikacja requires no interference from the operator.Dispatching PC - warehouse operator control centre

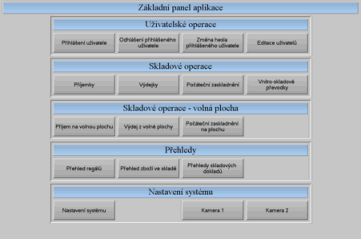

Aplikacja running on the warehouse operator PC is used as a basic interface for the operators. Umożliwia to display the goods overview in the whole warehouse, or in each shelf, the history of material receipt/issue, goods search według specified criteria and additional operacje. The system data is stored in a standard database format MS SQL.

Aplikacja running on the warehouse operator PC is used as a basic interface for the operators. Umożliwia to display the goods overview in the whole warehouse, or in each shelf, the history of material receipt/issue, goods search według specified criteria and additional operacje. The system data is stored in a standard database format MS SQL.

- The system can be operated only by the warehouse operator, that is logged into the system (identified by login name and password). All warehouse operacje executed by the system are logged and archived włącznie the warehouse operator identifier, that executed the operation.

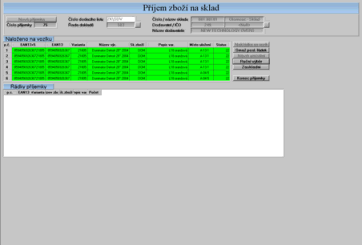

- The material receipt record is based on the bar code reader. Komunikacja of the system with the bar code reader is based on wireless connection. The recorded material is then displayed in the receipt protocol (patrz obrazek: the receipt protocol).

- The warehouse system executes most of the operations automatically. Some special operation are still executed under warehouse operator supervision because of the need of warehouse operations checking.

- The warehouse operator PC also displays the video feed from a Web camera, that provides the visual information about the warehouse space, and the warehouse operations that are currently being executed. This way the warehouse operator has more important information regarding the operations currently being executed in the warehouse.

- Aplikacja running on the warehouse operator PC secures the communication with the superior HELIOS system (receive, process and send the material issue orders and creating and sending the material receipt cards).

- based on this information aplikacja of the warehouse system provides the aggregate data for the HELIOS system w formie of receipt cards

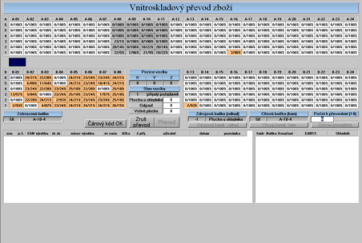

- receives the material issue polecenia from the HELIOS system and executes them (both material issue cards or inner material transfers) – patrz obrazek: the material issue card

- also umożliwia to finalize the unfinished material issue orders lub to enter new material issue order directly w systemie PROMOTIC. The wyniks of such orders are then transferred in to the HELIOS system.

- It is possible to execute both operacje affecting the HELIOS system and independent warehouse operations. Namely these are the operations transfering the goods inside the warehouse (the total status of the goods is not changed) – patrz obrazek: the inner material transfer card.

- The system provides the operators with the overview reports:

- the goods in each shelf and total in the warehouse

- executed material receipts / material issue orders

- searching for the placement of specific goods

- additional overviews, filters and reports

- The system and diagnostics narzędzia, alarm and event system and system parameter management (prawa dostępu for each warehouse operator, itd.) are also included in the system. The system parameter ustawienie can be executed only by użytkownik with administrator rights.

- The warehouse system also umożliwia remote servicing of application SW (via VPN klient in enterprise intranetu). This way it is possible to provide quick and operative servicing by the supplier of the warehouse system.

The material receipt opis:

- the warehouse operator reads and records the bar code of the received goods.

- the system processes the bar code, identifies the goods type and offers ther operator the optimal place for storing such goods. The storage space is choosen based on the optimalization algorithm (warehousing strategy):

- the goods of the similar type into the same shelves, itd.

- often used goods into the closest space, itd. The warehousing strategy has been adopted to the customer specific needs.

- The warehouse operator can confirm the offered option, or can specify the warehouse position manually.

- The system executes the material receipt: the PC sends the stacker movement command into the Mitsubishi PLC

- After the operacja is finished successfully the report is generated and the information is transferred into the HELIOS system

The material issue opis:

- The material issue orders are received by the warehouse sytem from the HELIOS system. The material issue order is processed by the by the warehouse system and divided into each warehouse operacje.

- The system offers the warehouse operator the best option for material issue (według the optimalization algorithm). The warehouse operator can confirm the offered option or enter the material pozycja manually.

- The system then executes the material issue operations, and the operator does the final material check – by the barcode reader. This way the chance of an error is being minimised. If there is an error found the system helps the operator find the error causes (tzn. which operator did something wroong and when).

- After the operations are finished successfully the information is transferred into the HELIOS system.

Patrz również:

Nawigacja:

- Automated warehouse manipulator control system - Olpran Olomouc